Technology

Why Error-Proof Production Starts with an Alabama Robotics Engineering Company’s Automation Solutions

Every manufacturer wants a flawless production line, but human error and inconsistencies make that nearly impossible. That’s where automation steps in. A robotics engineering company in Alabama is transforming manufacturing with cutting-edge solutions that boost precision, efficiency, and reliability like never before.

Precision Calibration That Ensures Every Cut and Weld Is Exact

Small mistakes in cutting or welding can lead to costly rework, product failures, or safety issues. Traditional methods rely on human skill, which can vary from shift to shift. An Alabama robotics engineering company eliminates that risk by integrating precision calibration into its automation systems. Robots are programmed to make exact cuts and welds every time, ensuring every component meets strict specifications without variation.

This level of accuracy is critical in industries like aerospace, automotive, and heavy machinery, where even a fraction of a millimeter matters. Automated calibration removes inconsistencies, reduces material waste, and speeds up production without sacrificing quality. Whether it’s laser cutting, robotic welding, or CNC machining, advanced robotics guarantee consistency on every production run, no matter the scale.

Smart Sensors That Catch Defects Before They Reach Assembly

Quality control is often a reactive process, catching defects after they’ve already been made. But with smart sensors, potential flaws are identified in real time before they ever make it to assembly. A robotics engineering company in Alabama integrates high-tech vision systems and AI-powered sensors into automated workflows, ensuring immediate detection of misalignments, incorrect dimensions, or material inconsistencies.

By identifying defects at the earliest stage, manufacturers prevent expensive recalls, reduce waste, and eliminate slowdowns caused by rework. These intelligent sensors can analyze thousands of components per second, far beyond human capability, making production lines faster, smarter, and more reliable. The result? A streamlined manufacturing process where only flawless parts move forward.

Automated Quality Control That Works in Real-Time

Traditional quality control methods involve random sampling, which means some defects slip through unnoticed. Automation changes the game by implementing real-time quality control, where every single component is inspected without slowing down production. An Alabama robotics engineering company achieves this by combining machine vision, AI, and robotics to continuously analyze and verify every part in motion.

This proactive approach eliminates human error and ensures consistent product quality across every batch. Whether it’s identifying micro-cracks in metal, verifying paint finishes, or ensuring correct assembly, automated quality control maintains precision at high speeds. Manufacturers no longer have to rely on outdated inspection methods—automation delivers flawless results, ensuring that every product leaving the facility meets the highest standards.

High-Speed Robotics That Maintain Accuracy at Any Scale

Speed and accuracy often seem like opposites in manufacturing. The faster production moves, the more mistakes tend to happen. However, high-speed robotics solve this problem by maintaining precision even at rapid production rates. A robotics engineering company in Alabama designs robotic systems that operate at incredible speeds while ensuring accuracy at every step.

These advanced machines are used in everything from high-speed assembly lines to packaging and material handling. Unlike human workers who tire or slow down over time, robots perform consistently, handling repetitive tasks with unwavering precision. The result is higher output, faster turnaround times, and fewer errors—giving manufacturers the ability to scale production without compromising quality.

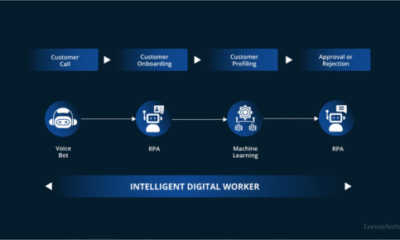

Adaptive Learning Systems That Continuously Improve Efficiency

Automation is no longer just about programming a machine and letting it run. Today’s most advanced robotic systems are equipped with adaptive learning technology, allowing them to improve over time. An Alabama robotics engineering company integrates AI-driven robotics that analyze performance data and make adjustments to enhance efficiency without human intervention.

For manufacturers, this means production lines that get smarter with every cycle. Robots can predict potential bottlenecks, optimize workflow, and fine-tune movements to reduce energy consumption and material waste. Unlike traditional machinery that requires constant recalibration, adaptive learning systems evolve, ensuring that operations become more streamlined and cost-effective with every passing day.

Custom Automation Solutions That Fit Each Manufacturer’s Needs

Every production facility is different, which means a one-size-fits-all automation system won’t cut it. A robotics engineering company in Alabama specializes in custom automation solutions designed to meet the specific needs of each manufacturer. Whether it’s integrating robotics into an existing production line or designing a fully automated system from the ground up, tailored solutions maximize efficiency and output.

From robotic arms for precision assembly to AI-powered conveyor systems for large-scale operations, custom automation ensures that manufacturers get exactly what they need to stay competitive. These solutions aren’t just about increasing speed—they’re about optimizing workflows, reducing costs, and ensuring that production lines run smoothly with minimal downtime.

You must be logged in to post a comment Login