Business

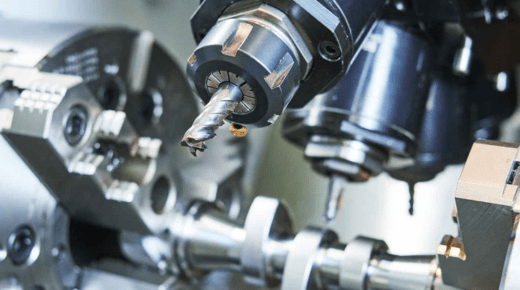

5 Advantages of Custom CNC Tooling for Your Business

Effective operations in manufacturing and production require precision, efficiency, and adaptability. Selecting the right tools directly impacts system performance, product quality, and overall productivity. For businesses focused on machining and assembly, custom CNC tooling offers a valuable solution to meet specific operational demands.

This post explores why partnering with companies offering custom CNC tooling solutions can significantly benefit your business.

Tailored Solutions for Unique Requirements

Every manufacturing process has its own unique challenges and specifications. Generic, off-the-shelf tooling often falls short when it comes to precision and adaptability. Companies specializing in custom CNC tooling design their products specifically to meet your operational needs.

For example, if you deal with hard-to-machine materials or complex geometrical designs, custom tooling ensures the tools are built with the right specifications to work seamlessly within your production setup. This level of precision reduces errors, minimizes material waste, and ensures superior output quality.

Enhanced Durability and Tool Life

The lifespan and resilience of tools are critical factors when selecting machining equipment. Custom CNC tools are crafted from materials optimized for your specific processes and workloads. This typically results in better wear resistance, heat tolerance, and overall strength compared to standard tools.

Enhanced durability translates to fewer tool changes, reduced downtime, and lower maintenance costs—directly contributing to increased production efficiency. When tools are built to last longer under demanding conditions, businesses see improved cost-effectiveness over time.

Boosted Operational Efficiency

When tools are optimized for specific applications, businesses benefit from improved operational efficiency. Custom CNC tooling reduces setup times, enhances machining speed, and achieves optimal cutting conditions more effectively than standard tooling.

For instance, tools designed specifically for high-speed operations can maintain exceptional accuracy while saving time on repetitive tasks. This heightened efficiency not only streamlines production but allows you to meet tight deadlines without compromising quality.

Consistent Product Quality

Consistency is key, especially in industries where precision is non-negotiable. Custom CNC tooling ensures that dimensional accuracy and surface finishes are maintained consistently across all production runs.

Whether producing high volumes or small batches of intricate parts, tools made for your specific processes minimize variations, improving overall product uniformity. This advantage is particularly significant for industries such as aerospace, automotive, and medical device manufacturing, where stringent quality standards are mandatory.

Improved Cost Management

Although custom CNC tooling may require upfront investment, its long-term benefits often outweigh the initial expense. Longer-lasting tools, improved efficiency, and enhanced product quality reduce overhead costs significantly over time.

Additionally, better-performing tools reduce waste and rework, ultimately cutting production costs. Custom tool manufacturers often provide ongoing support, ensuring that the tools are continuously optimized to align with evolving production needs.

Final Thoughts

Investing in custom CNC tooling is more than a choice of tools; it’s a strategic decision to improve production efficiency, lower operational costs, and ensure consistent quality. By partnering with a company that specializes in custom tooling, procurement managers can unlock the potential for smarter manufacturing practices tailored to their unique needs.

Are you ready to boost your manufacturing efficiency? Reach out to custom CNC tooling providers to discover the advantages tailored solutions can deliver for your business.

You must be logged in to post a comment Login